Electric Motors: The Hidden Force Driving the World

Nov 16, 2024

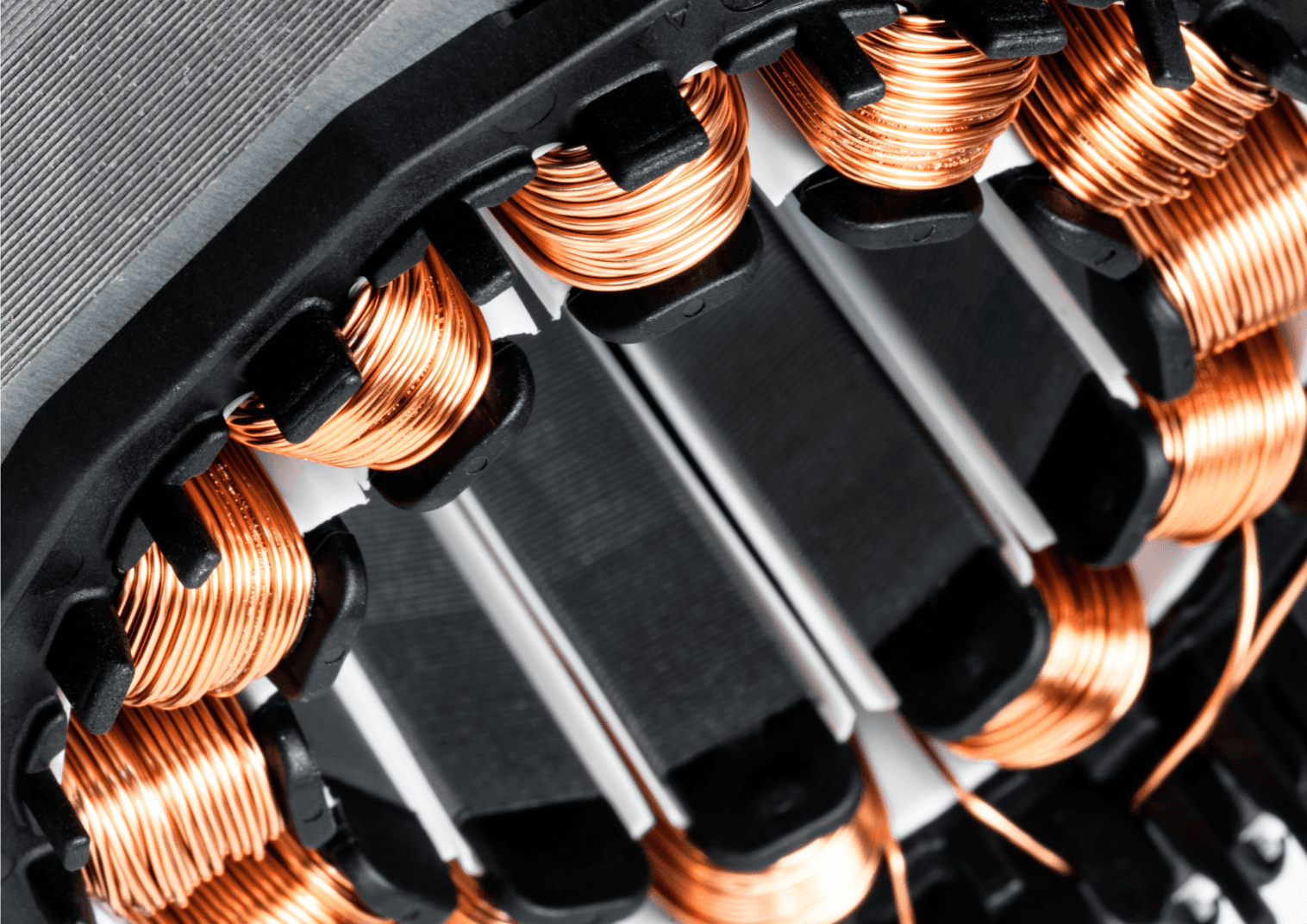

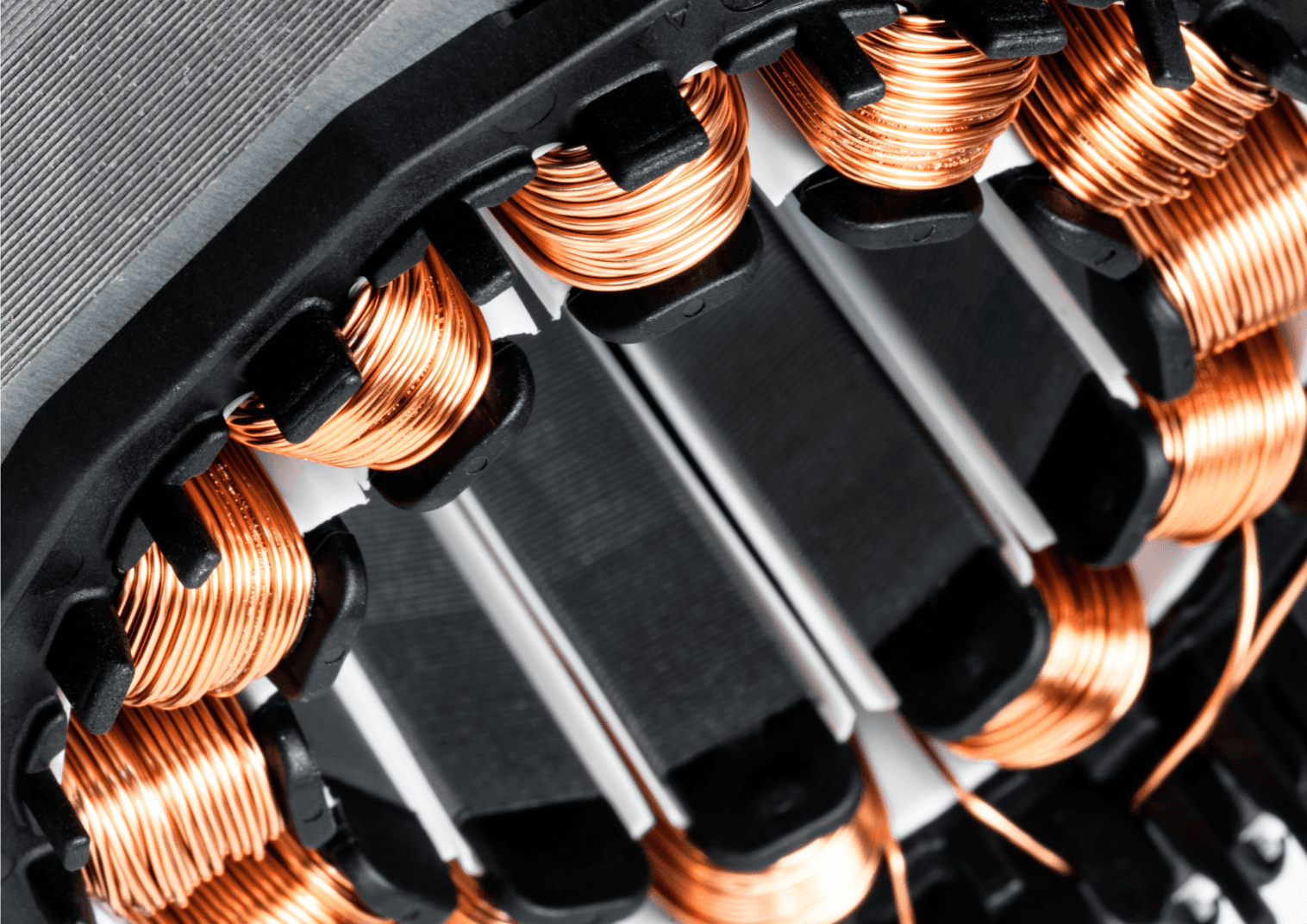

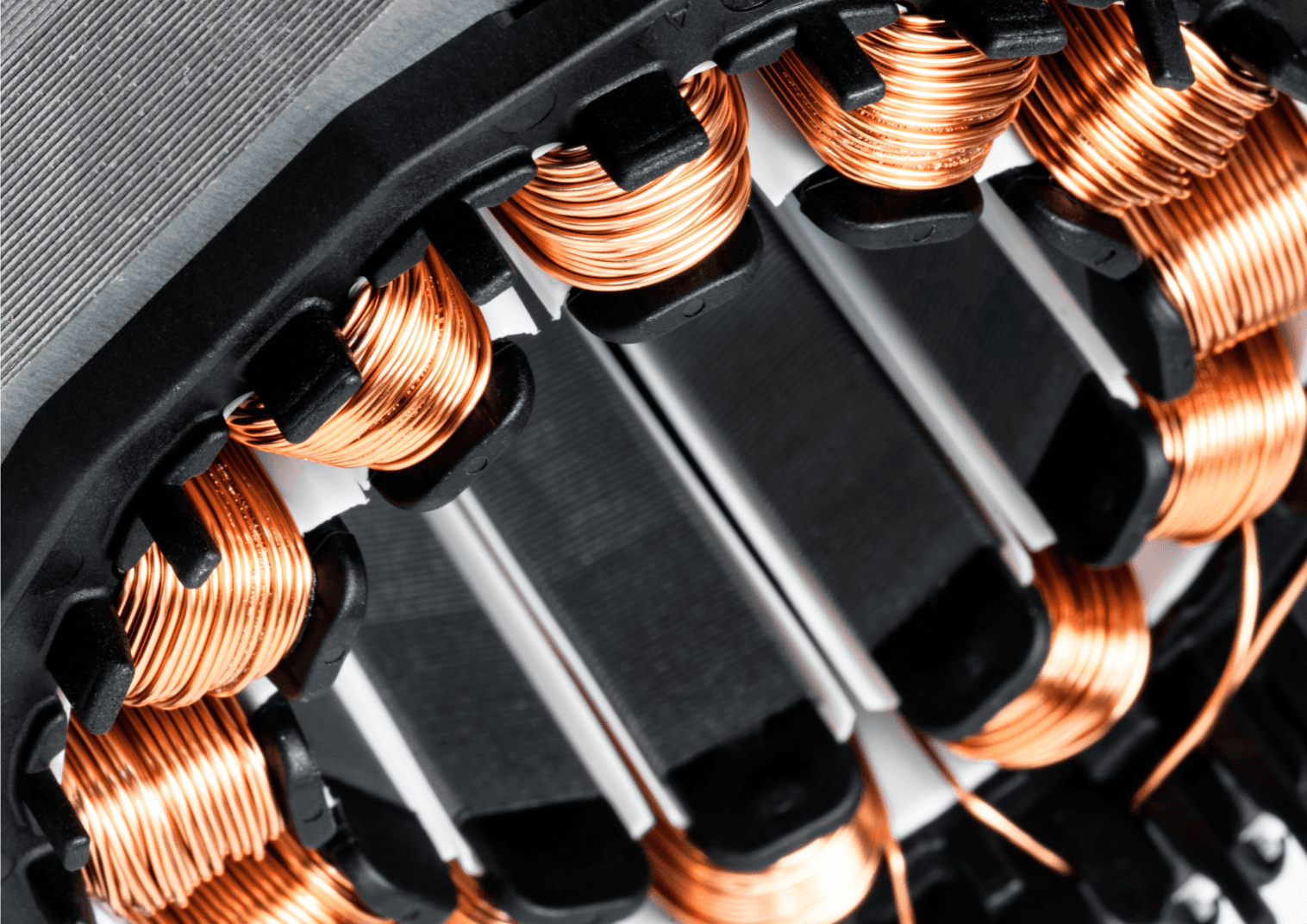

While semiconductors grab headlines, motors silently power 47% of the world's energy consumption. From the robots in our factories to the pumps in our dishwashers, these vital components form the literal moving parts of our economy. Yet the supply chain to purchase or manufacture these motors is not fully in our control.

Why Motors Matter Now More Than Ever

The next wave of automation isn't just coming—it's here. Humanoid robots from companies like Tesla and Figure are promising to reshape manufacturing. Autonomous drones are revolutionizing delivery and surveillance. Smart factories are automating production at unprecedented scales. What do they all have in common? High-performance electric motors.

Modern robotics demand precision components that can deliver microscopic movements one moment and explosive power the next. A single humanoid robot may contain hundreds of motors. Now multiply that by the millions of units companies plan to produce and you quickly start to see the scale of things.

A Massive Risk

Here's the problem: Foreign nations dominates the motor supply chain at every level. They control:

- The majority of rare earth material processing

- Vast manufacturing expertise built over decades

- Unmatched production scale and cost advantages

This isn't just about economics—it's about national security. The same motors that power civilian robots are critical for military drones, automated defense systems, and countless other strategic applications. Our dependence on majority Chinese motors is a strategic vulnerability we can no longer ignore.

With potential tariffs on foreign exports causing massive cost increases, US-based companies without domestic alternatives with competitive pricing and lead-times risk swift deaths.

Rebuilding our Industrial Might

How can we start to address some of these risks before our supply?

Infrastructure

We need modern factories equipped with advanced automation and quality control systems. These facilities must be energy-efficient and environmentally sustainable—not just to meet regulations, but to compete globally.

This means not just adopting new and advanced robotics, but embracing decades of tooling advancements that we are behind on.

Workforce

The skills gap is real. We need:

- Technical education programs that target motor design and manufacturing

- Apprenticeship programs partnering with existing manufacturers

- University research programs focused on next-generation motor technology

Technology Investment

American manufacturing won't compete on labor costs, but you would be surprised: that's not where the majority of costs are. Factories in China are extremely automated and efficient. We have to win through superior technology:

- Advanced manufacturing processes embracing AI and automation to reduce reliance on fixed tooling where possible

- New motor designs that maximize efficiency and performance

- Novel materials that reduce dependence on rare earth elements

The Time to Act Is Now

The robotics revolution is accelerating. The next generation of humanoid workers heading to market will each require dozens of precision motors—from microscopic actuators for finger movements to powerful drives for lifting and walking. Multiply this by the millions of units planned for manufacturing and logistics, and the scale becomes staggering.

But this goes far beyond humanoids. Commercial delivery drones need lightweight, high-performance motors to stay airborne while carrying packages. Military drones require millions of drones for modern warfare that has quickly evolved to mean massive swarms of autonomous, low-cost, systems. Every automated warehouse, every smart factory, every modern industrial facility depends on motors for their basic operations—from conveyor systems to robotic arms to automated guided vehicles.

The question isn't whether we'll need these motors—it's whether we'll be able to produce them domestically when we need them most. The cost of inaction isn't just measured in dollars and market share—it's measured in technological independence and national security.

What is Ethereal's role in this?

We are focused on building an autonomous factory to design, manufacture, and assemble electric motors in the United States.

We believe this is critical to the future of the nation, and are proud to produce a core building block needed for so many industries.

We are starting by producing a singular sized BLDC and Stepper Motor in volume to provide drone, robotics, and industrial automation companies with a US-based alternative.

If you are interested in working with us, please contact us!

Electric Motors: The Hidden Force Driving the World

Nov 16, 2024

While semiconductors grab headlines, motors silently power 47% of the world's energy consumption. From the robots in our factories to the pumps in our dishwashers, these vital components form the literal moving parts of our economy. Yet the supply chain to purchase or manufacture these motors is not fully in our control.

Why Motors Matter Now More Than Ever

The next wave of automation isn't just coming—it's here. Humanoid robots from companies like Tesla and Figure are promising to reshape manufacturing. Autonomous drones are revolutionizing delivery and surveillance. Smart factories are automating production at unprecedented scales. What do they all have in common? High-performance electric motors.

Modern robotics demand precision components that can deliver microscopic movements one moment and explosive power the next. A single humanoid robot may contain hundreds of motors. Now multiply that by the millions of units companies plan to produce and you quickly start to see the scale of things.

A Massive Risk

Here's the problem: Foreign nations dominates the motor supply chain at every level. They control:

- The majority of rare earth material processing

- Vast manufacturing expertise built over decades

- Unmatched production scale and cost advantages

This isn't just about economics—it's about national security. The same motors that power civilian robots are critical for military drones, automated defense systems, and countless other strategic applications. Our dependence on majority Chinese motors is a strategic vulnerability we can no longer ignore.

With potential tariffs on foreign exports causing massive cost increases, US-based companies without domestic alternatives with competitive pricing and lead-times risk swift deaths.

Rebuilding our Industrial Might

How can we start to address some of these risks before our supply?

Infrastructure

We need modern factories equipped with advanced automation and quality control systems. These facilities must be energy-efficient and environmentally sustainable—not just to meet regulations, but to compete globally.

This means not just adopting new and advanced robotics, but embracing decades of tooling advancements that we are behind on.

Workforce

The skills gap is real. We need:

- Technical education programs that target motor design and manufacturing

- Apprenticeship programs partnering with existing manufacturers

- University research programs focused on next-generation motor technology

Technology Investment

American manufacturing won't compete on labor costs, but you would be surprised: that's not where the majority of costs are. Factories in China are extremely automated and efficient. We have to win through superior technology:

- Advanced manufacturing processes embracing AI and automation to reduce reliance on fixed tooling where possible

- New motor designs that maximize efficiency and performance

- Novel materials that reduce dependence on rare earth elements

The Time to Act Is Now

The robotics revolution is accelerating. The next generation of humanoid workers heading to market will each require dozens of precision motors—from microscopic actuators for finger movements to powerful drives for lifting and walking. Multiply this by the millions of units planned for manufacturing and logistics, and the scale becomes staggering.

But this goes far beyond humanoids. Commercial delivery drones need lightweight, high-performance motors to stay airborne while carrying packages. Military drones require millions of drones for modern warfare that has quickly evolved to mean massive swarms of autonomous, low-cost, systems. Every automated warehouse, every smart factory, every modern industrial facility depends on motors for their basic operations—from conveyor systems to robotic arms to automated guided vehicles.

The question isn't whether we'll need these motors—it's whether we'll be able to produce them domestically when we need them most. The cost of inaction isn't just measured in dollars and market share—it's measured in technological independence and national security.

What is Ethereal's role in this?

We are focused on building an autonomous factory to design, manufacture, and assemble electric motors in the United States.

We believe this is critical to the future of the nation, and are proud to produce a core building block needed for so many industries.

We are starting by producing a singular sized BLDC and Stepper Motor in volume to provide drone, robotics, and industrial automation companies with a US-based alternative.

If you are interested in working with us, please contact us!